Cemented carbide, commonly understood for its longevity and firmness, plays a necessary function across numerous markets. Composed primarily of tungsten carbide (WC) particles bonded with a metal binder, such as cobalt, cemented carbide incorporates the stamina of tungsten with the strength of other steels. The structure of cemented carbides can be tailored to fit details applications, causing the production of selections like YG6, YG15, and YG20 tungsten carbide. YG6, for circumstances, is understood for its high wear resistance and is often made use of in cutting devices and equipment where accuracy is important. Similarly, YG20 and YG15 tungsten carbide are employed depending upon the required equilibrium between hardness and sturdiness, making them extremely sought after in numerous industrial circumstances.

The term carbide, generally, refers to a class of substances developed by the chemical combination of carbon with an extra electropositive element. In the majority of useful applications, carbides are developed when steels like tungsten or titanium are combined with carbon, creating materials like tungsten carbide. Tungsten carbide itself is a dark grey to black, dense material that flaunts impressive firmness, ranking second only to ruby in terms of material firmness. With a density typically around 15.6 g/cm THREE, tungsten carbide is substantially denser than steel, allowing it to be made use of in applications requiring significant wear resistance and stamina. This one-of-a-kind mix of homes is why tungsten carbide is often referred to as a hard metal, a term that incorporates various products known for their outstanding hardness and sturdiness.

Tungsten powder and carbon are blended with each other and warmed to a temperature high adequate to precipitate the development of tungsten carbide. The enhancement of cobalt or nickel serves as a binder to hold the tungsten carbide fragments with each other, resulting in a solid material that is both immune and solid to abrasion.

Tungsten carbide is widely known for its considerable commercial applications. From mining to production, the sturdiness of tungsten carbide makes it optimal for creating wear parts that sustain severe conditions.

Tungsten carbide plays a crucial role in the production of specialized parts like blocks, plates, tubes, and rods. The flexibility of the material enables it to be made into various forms, dealing with distinct industrial demands, consisting of cemented carbide buttons and bushings used in tooling applications. These parts improve performance and efficiency when machining various other materials, making them invaluable in making processes. For example, tungsten carbide EDM (Electrical Discharge Machining) blocks are generally utilized for intricate electric discharge machining applications, where precision is of utmost importance.

In current years, the popularity of tungsten carbide has actually surged in other locations also, such as customer products. Tungsten carbide rings, for instance, have obtained emotional worth as interaction and wedding celebration bands because of their sturdiness and scratch resistance. The material's capacity to keep a great finish for longer durations than conventional priceless metals has actually made it a preferred option for lots of pairs searching for sturdy yet visually pleasing choices.

The production of tungsten carbide parts, such as saw blades, bushings, and tips, is substantial to industries that focus on both performance and high quality. In the globe of construction and mining, carbide saw tips are necessary for tools utilized in puncturing difficult products. Being wear-resistant and able to maintain intensity longer than various other materials, tungsten carbide saw tips are optimal for maintaining efficiency and minimizing downtime during operations.

In addition, the advancement in cemented carbide production has actually enabled new developments, such as the proposition for carbide blocks, strips, and preforms that accommodate extremely details applications. Businesses depend on personalized carbide preforms, which are manufactured to fit special requirements, making certain that the end product does ideally in its designated application. The surge of manufacturers producing carbide blanks and strips has additionally changed the market characteristics, providing clients with even more alternatives tailored to their certain demands.

The contrast in between carbide and tungsten carbide discloses some vital differences. While carbide can refer to any carbon compound with a metal, tungsten carbide distinctly signifies the mix of tungsten with carbon.

Apart from tungsten carbide, one more appropriate material in the discussion of hard metals is Stellite, frequently known for its excellent wear resistance and heat resistance in difficult settings. Stellite, a cobalt-chromium alloy, is regularly made use of in applications where both thermal and wear resistance are critical. For circumstances, Stellite 6 and Stellite 6B versions serve one-of-a-kind functions in sectors where devices deal with extreme conditions. The main difference depends on the make-up of the alloys and their particular resistance to heat and abrasion. While tungsten carbide excels in hardness, Stellite materials are often favored for applications needing both strength and resistance to ecological get more info aspects.

As industries continually look for materials that can offer sturdiness and accuracy, cemented tungsten carbide stays a preferred option. The combination of high wear resistance, sturdiness, and thermal stability has actually maintained tungsten carbide's status at the leading edge of commercial products.

Tungsten carbide likewise has a remarkable existence in the jewelry industry. Its unique properties, such as scratch resistance and high gloss, have made it an increasingly preferred option for wedding event bands and various other fashion devices. The capability to achieve a sleek finish combined with its enduring nature permits tungsten carbide jewelry to preserve its visual charm with time. This crossover from industrial usage to individual things exhibits the flexibility of tungsten carbide across numerous market industries.

In regards to its thermal properties, tungsten carbide has a high melting point, generally around 2,870 levels Celsius (5,200 degrees Fahrenheit), which gives excellent stability in high-temperature applications. Such thermal security makes tungsten carbide an outstanding prospect for cutting and machining operations that run into enhanced friction and heat. Its capacity to sustain anxiety and heat without deforming additional boosts its worth in environments where standard tools might stop working.

The continuous research and advancement in carbide more info innovation guarantee to unveil also a lot more applications and improvements for products like tungsten carbide, leading to developments that can reshape manufacturing processes. Inevitably, as the demand for sturdy, high-performance products grows, tungsten carbide and its numerous forms will likely stay at the center of material scientific research and design, driving requirements for efficiency and efficiency in production and beyond.

In recap, tungsten carbide and cemented carbide are cornerstones in the industry, reflecting the breakthroughs in material scientific research and design. The many applications varying from tools and wear parts to consumer products show their value in everyday life. With recurring research and growth, the landscape for tungsten carbide remains to develop, going after brand-new applications and technologies that broaden its reach. As markets around the globe remain to require efficiency and toughness, materials like tungsten carbide and its various types will most certainly remain main to fulfilling these needs. The value of understanding the unique residential properties and applications of these hard metals can not be understated, as they remain to reinvent sectors and boost productivity across the board.

Mara Wilson Then & Now!

Mara Wilson Then & Now! Patrick Renna Then & Now!

Patrick Renna Then & Now! Romeo Miller Then & Now!

Romeo Miller Then & Now! Yasmine Bleeth Then & Now!

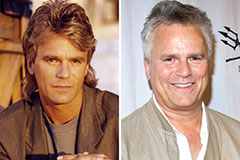

Yasmine Bleeth Then & Now! Richard Dean Anderson Then & Now!

Richard Dean Anderson Then & Now!